PCB Project 1

General Description

Welcome to my PCB design portfolio, showcasing my experience in designing a custom PCB for various uses

Whole Project Description

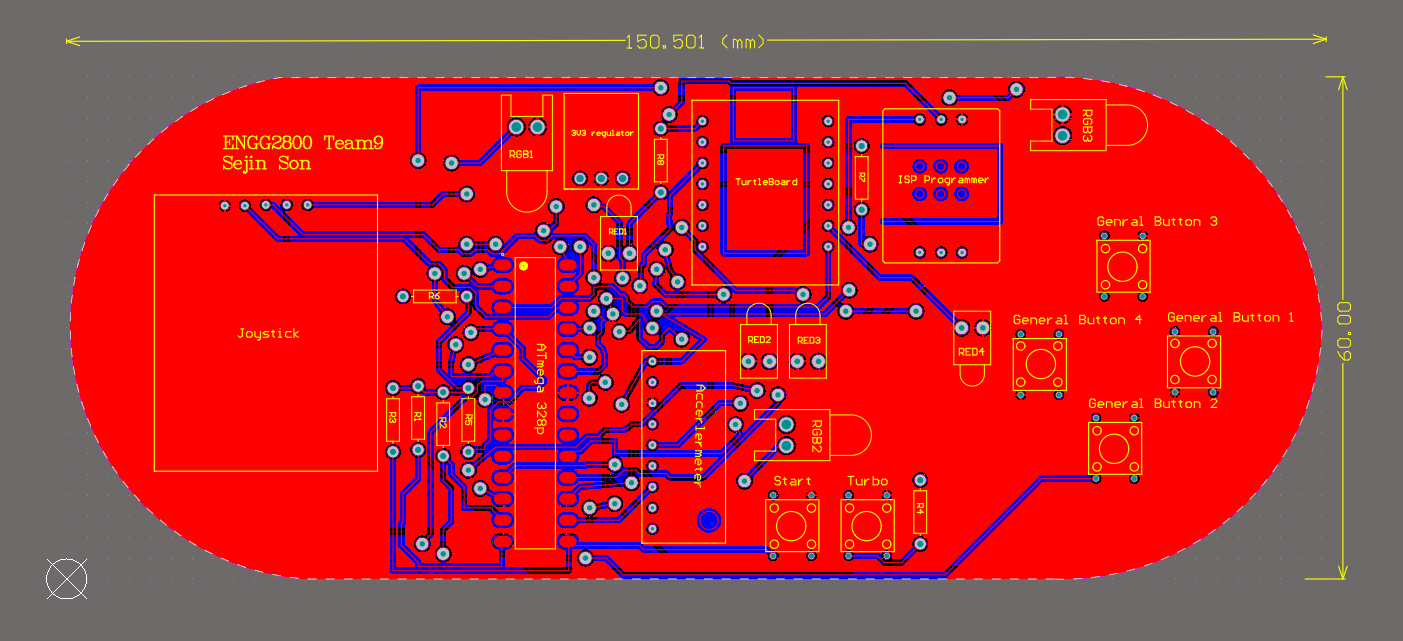

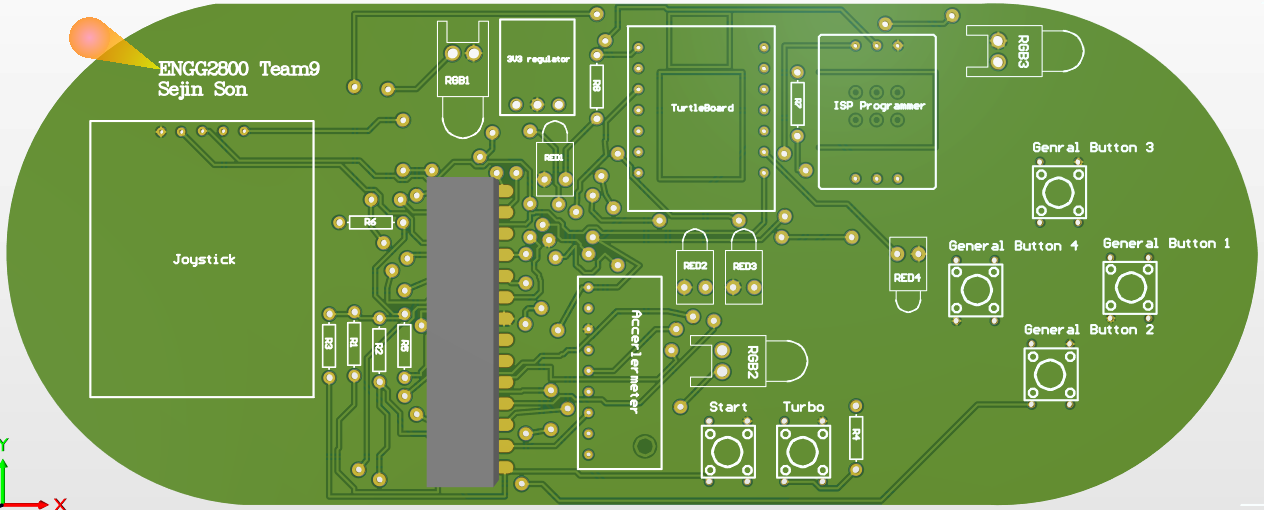

The custom input device project aims to create a versatile gaming controller compatible with various gaming platforms. Featuring six momentary pushbuttons, a 2-axis joystick, and a 3-axis accelerometer, the controller offers intuitive controls and enhanced gameplay experiences. Turbo functionality allows for rapid button presses, while toggle switches enable seamless transitions between analog and DPad modes. Visual feedback through LEDs and customizable RGB lighting adds a personalized touch to the gaming experience. With configuration options for joystick deadzone and analog-to-DPad conversion thresholds, the controller caters to diverse gaming preferences for an immersive gaming experience.

Design Highlight

1. Universal Compatibility: Built to work seamlessly with all gaming systems supporting a standard USB controller, the device utilizes the industry-standard HID protocol for USB communication, ensuring broad compatibility across various gaming platforms.

2. Enhanced Gameplay Controls: Featuring six momentary pushbuttons, a 2-axis joystick with a pushbutton, and a 3-axis accelerometer, the controller offers intuitive and responsive gameplay controls. Additionally, toggle switches allow users to switch between analog and DPad modes, as well as enable or disable the accelerometer as per their preference.

3. Turbo Functionality: In response to the need for rapid button presses in certain games, the controller incorporates turbo mode for the four general-purpose buttons. Users can easily toggle turbo mode for individual buttons, enabling rapid and continuous button presses for enhanced gameplay performance.

4. Visual Feedback: Equipped with LEDs corresponding to each general-purpose button, the controller provides visual feedback on turbo mode status. LEDs indicate whether turbo mode is enabled, disabled, or actively being utilized, enhancing user awareness during gameplay.

5. Customizable RGB Lighting: Adding a personalized touch to the gaming experience, the controller features RGB LEDs spread underneath the controller body. Users can customize the brightness and color of these LEDs using a GUI application on the PC, with settings retained in non-volatile memory for consistent lighting preferences.

6. Configuration Flexibility: Offering users flexibility in configuration, the controller allows adjustment of joystick deadzone and analog-to-DPad conversion thresholds via GUI software. These configurations are retained across power cycles, ensuring a tailored gaming experience for each user.

PCB Design Experience

The development of the custom input device involved a comprehensive PCB design process, leveraging advanced techniques and considerations for optimal functionality and user experience:

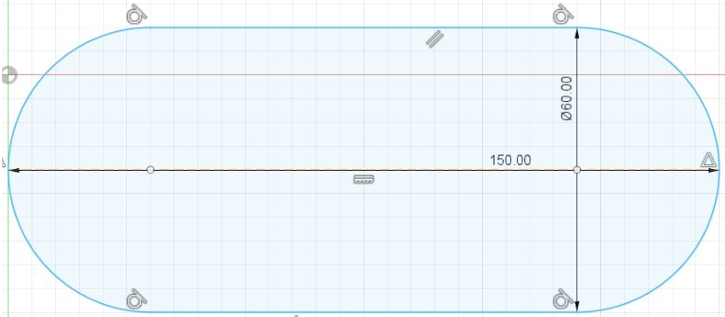

1. Component Integration: Careful integration of components was crucial to ensure seamless functionality and ergonomic design. Components such as pushbuttons, toggle switches, joysticks, and accelerometers were strategically placed to maximize usability and comfort during gameplay.

2. Signal Integrity Management: Attention to signal integrity management was paramount to minimize signal interference and ensure reliable data transmission. Proper grounding, signal routing, and impedance matching techniques were employed to maintain signal integrity across the PCB.

3. Power Optimization: Efficient power management techniques were implemented to optimize power consumption and extend battery life. Low-power design principles were employed to minimize power wastage and enhance the device's longevity during extended gaming sessions.

4. Testing and Validation: Rigorous testing and validation procedures were conducted to ensure the reliability and performance of the PCB design. Functional testing, signal analysis, and compatibility testing were performed to verify the functionality and compatibility of the device with various gaming systems.

5. Compliance: Ensuring compliance with industry standards, particularly RoHS requirements, can be challenging when sourcing components and materials.

I overcame this by carefully vetting suppliers, verifying component compliance documentation, and conducting periodic audits to ensure ongoing compliance throughout the design process.

6. Documentation and Compliance: Thorough documentation of the PCB design process, including schematics, layout files, and fabrication notes, was maintained to ensure compliance with industry standards and facilitate future revisions or modifications. Compliance with regulatory requirements and industry standards was ensured throughout the design process.

PCB Project 2

Whole Project Description

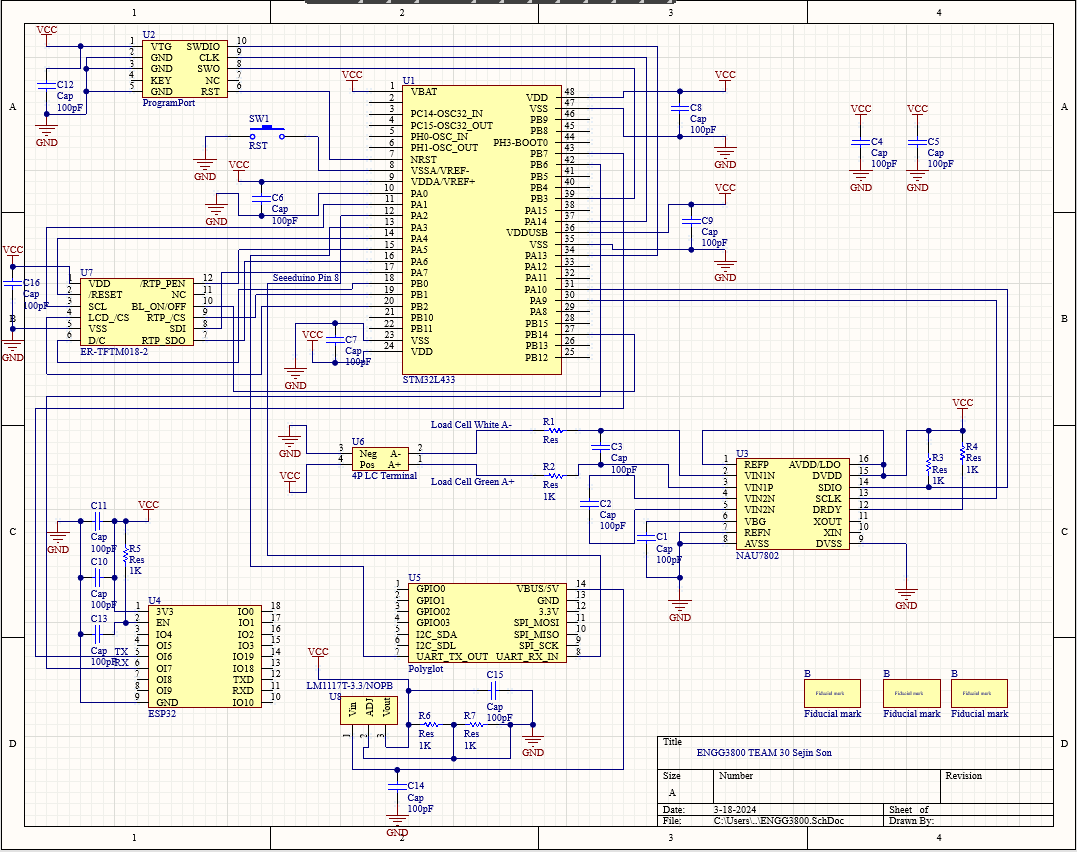

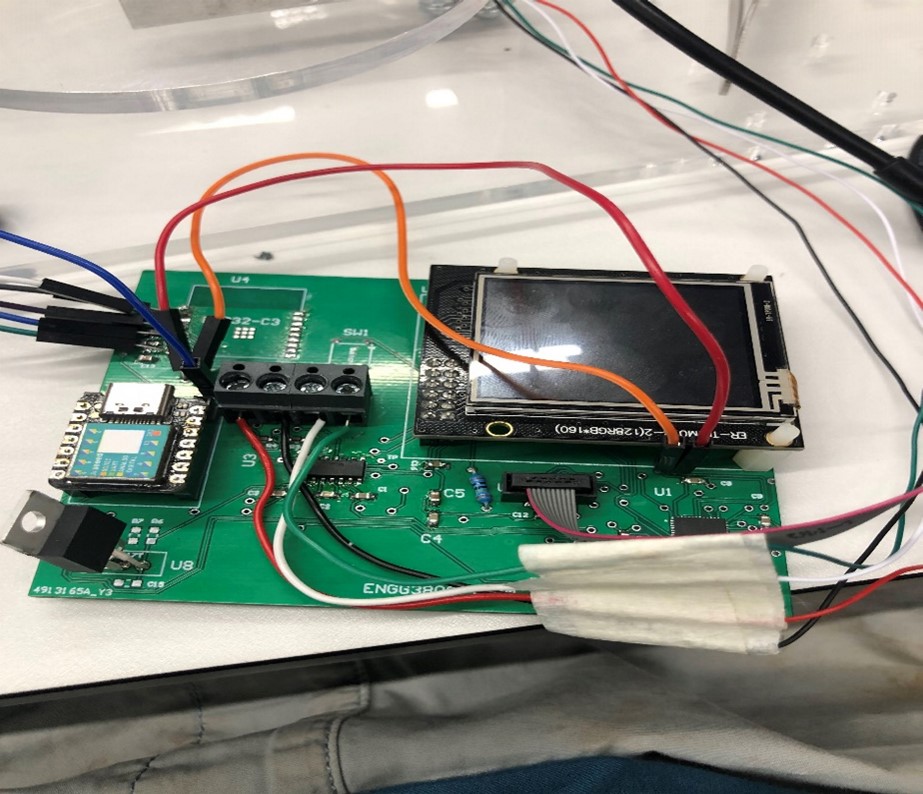

The Massify project focuses on developing a versatile weighing device equipped with various operational modes to cater to different applications. The device utilizes an ETSG 28-11-03 load cell for precise weight measurement, interfacing with a TFT LCD display with a resistive touch screen for user interaction. Powered by an STM32 microcontroller, the device offers functionalities such as general weighing mode, counting mode, pass/fail mode, and calibration.

Design Highlight

1. Versatile Operating Modes: One of the key design highlights of the Massify device is its versatility in operating modes. From general weighing to counting mode and pass/fail mode, the device caters to a wide range of weighing needs, providing users with flexibility and customization options.

2. Intuitive User Interface: The device features an intuitive user interface with a TFT LCD display and resistive touch screen, allowing users to navigate between different modes and adjust settings with ease. Clear indicators and icons provide visual feedback, ensuring a seamless user experience.

3. Precise Weight Measurement: Equipped with an ETSG 28-11-03 load cell and a high-resolution ADC, the Massify device delivers precise weight measurements with an accuracy of +/-10g across the entire measurement range. Users can rely on the device for accurate and consistent results in various weighing scenarios.

4. Seamless Connectivity: The device offers both wired and wireless connectivity options, allowing users to communicate with the PC software via USB or WiFi. With MQTT over secure websockets protocol, users can access all functionality remotely, enhancing convenience and accessibility.

5. Calibration Wizard: The device features a calibration wizard that guides users through the calibration process step-by-step, ensuring accurate and reliable weight measurements. Users can calibrate the device easily via the touchscreen interface or PC software, minimizing setup time and effort.

6. Robust Construction: Constructed using a custom-designed PCB and mounted on provided acrylic hardware, the Massify device is robust and durable, capable of withstanding rigorous use in various environments. Its compact and ergonomic design ensures easy integration into existing workflows.

PCB Design Experience

Our team brings extensive PCB design experience to the development of the Massify weighing device, leveraging advanced techniques and methodologies to ensure optimal performance and reliability:

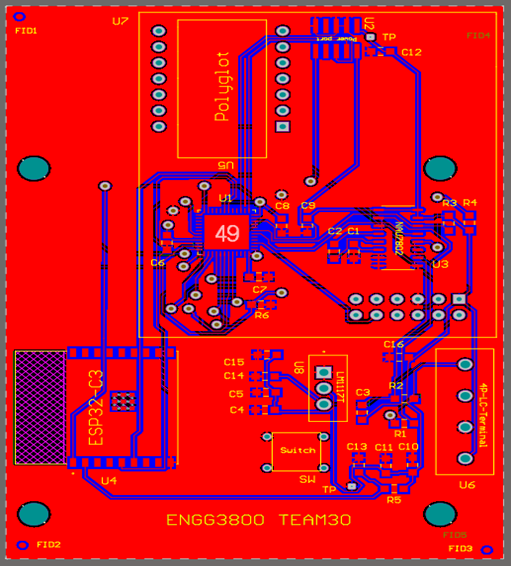

1. Schematic Design: We meticulously design schematics using industry-standard tools, ensuring proper connectivity and functionality of all components. Our thorough approach to schematic design lays the foundation for a robust and reliable PCB layout.

2. PCB Layout Optimization: We employ advanced PCB layout techniques to optimize space utilization, minimize signal interference, and ensure manufacturability. By carefully placing components and routing traces, we achieve high-density and high-performance PCB layouts.

3. Signal Integrity Management: We pay special attention to signal integrity management, including impedance matching, differential signaling, and ground plane optimization. Our focus on signal integrity ensures minimal signal distortion and reliable operation of the device.

4. Prototype Testing and Validation: We prototype and test PCB designs to validate functionality, performance, and reliability. Through comprehensive testing and debugging, we identify and address any issues or errors in the design, ensuring a stable and robust final product.

5. Documentation and Traceability: We maintain thorough documentation throughout the PCB design process, including design files, schematics, layout files, and fabrication notes. Our documentation ensures traceability and facilitates future revisions or modifications.

6. Manufacturability Considerations: We design PCBs with manufacturability in mind, considering factors such as panelization, solder mask, silkscreen, and assembly processes. By collaborating closely with manufacturers, we ensure smooth production and assembly of PCBs.